Designing An Efficient and Effective 911 Control Room: A Case Study

- Axel Trujillo

- Jan 25, 2024

- 4 min read

Updated: Jan 23

Installation No. 24915

About the client, a police organization:

Our client is a police organization that was looking to build a new 911 control center. To support the needs of its population, it employs more than 200 police officers, and provides them with various resources that can address some their local concerns.

About the project:

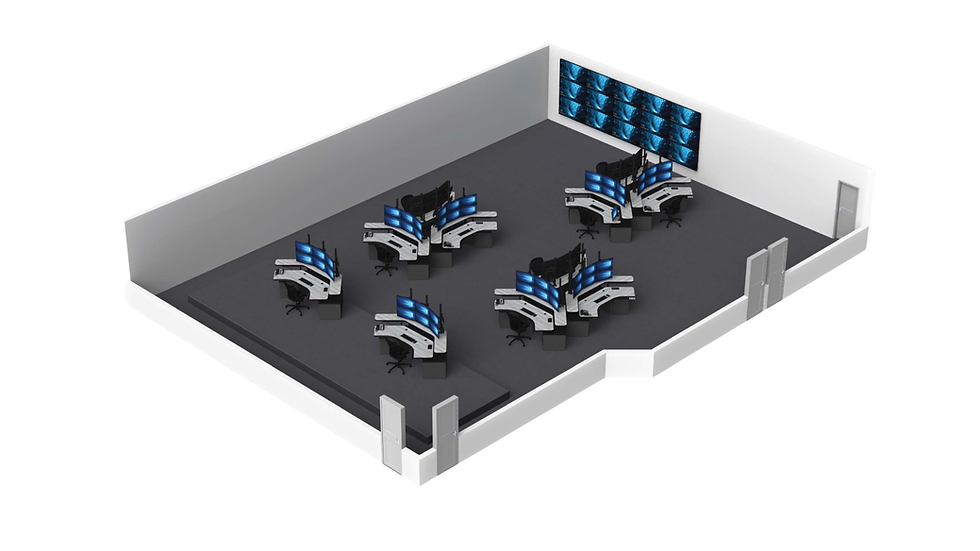

The project involved designing and manufacturing a newly renovated 911 control room that could accommodate 10 heavy duty control consoles to offer a more adequate workplace for visitors and employees. This new center would group all the teams who work as part of the police service.

The consoles were to be arranged in the following configuration, 10 control consoles setup in 3 rows, leaving enough space for foot-transit inside the control center. 2 consoles would be placed side by side leaving enough space for a storage unit between the 2 consoles.

As for the requirements of the specialized furniture, the most important include:

10 dispatcher consoles with a large worksurface area in cockpit shape.

Each console should be equipped with 4 CPU enclosures intended for intensive use and include a sliding tray.

4 actuators with a lift capacity of 260 pounds each.

High pressure laminate with Greenguard certification.

Secure cable management integrated.

Integrated power solution.

Include a storage cabinet that can fit between 2 consoles.

Integrated heating system.

Monitor arms compatible with VESA 100x100 mounts that can be adjusted laterally and vertically.

Include a status light with a minimum of 2 colors, white and red.

About the solution:

Our clients chose our heavy-duty consoles to build their modernized 911 control room because they met their specific requirements and could be arranged in their desired configuration to maximize the available space.

Our Transit consoles features two large heavy duty work surfaces. A primary and a secondary work surface. Both can be individually height adjusted to fit the operator’s ergonomic needs.

The primary worksurface is where the operator can place their keyboards and other utensils. Additionally, the primary worksurface is houses the keypads that control the height adjustments, the heating system and the fans integrated on the worksurface.

The secondary worksurface supports the weight of the 3 sturdy monitor arms which can be adjusted to the operator’s desired height and depth. The poles where the monitor arms are mounted, also hold the weight of both the task lamp and the status light.

To support the combined weight of both worksurfaces, as well as the constant and intensive use operators will give their control consoles, our furniture is manufactured with a 12-gauge steel substructure. This material ensures its durability and prevents the worksurface from deforming over time.

Our consoles have more than enough room to house the required CPUs while leaving room to spare in case our client chooses to add more computers to their setup. The CPU enclosures feature a sliding tray, making it easy to access the IT equipment without causing downtime.

Since the substructure is made from steel, al the critical equipment can be secured under lock and key. The CPU enclosures are accessible on the front and the back of the consoles.

On the left side of the console, the client can take advantage of the personal storage included. It is the perfect location to keep personal belongings and files.

The heating system is located at the bottom of the console, so that when activated, the heat rises and makes the workstation more comfortable during the winter months.

To connect the CPUs underneath the console to the monitors mounted on the secondary worksurface, the console features a pathway that allows cable to run alongside the substructure. To provide cable management and secure the cables during motion while the operator adjusts the height of the console, the furniture includes cable chains to protect the equipment.

About the result:

Our client implemented 10 of our control consoles to create a state-of-the-art control center. Since our consoles are made from steel and high-pressure laminate, they can endure heavy duty use for years to come.

With the ergonomic features of our control consoles, our client can provide the operators in the room with a workstation that adapts to their specific needs and requirements.

Combining the height adjustability of both work surfaces, and the adaptability of the monitor arms, users can rearrange their console throughout their shift. For example, if the operator wishes to work while standing, they can do so, and the console changes with the push of a button.

With the dual work surfaces of the console, operators can take advantage of a wide workspace with enough room to place all their tools. Since the work surface is made from High pressure laminate, users can work without worrying about scratching the surface. Also, with the secondary worksurface, operators don't have to concern themselves with monitor cables getting in the way of their work.

The integrated heating system at the bottom of the console, and the fans installed directly on the primary worksurface allow the operators to adjust the temperature at their desired levels.

Thanks to the secure cable management our client’s control center ensures their IT equipment stays safe, but also easily accessible to carry maintenance operations.

The open floor layout chosen by our client encourages communication between the operators. Additionally, the implementation of status lights helps the supervisor to easily identify if a situation requires their attention.

Are you building a new control room for 911?

It wasn’t mentioned above but we have more than 25 years of experience in designing and manufacturing specialized furniture for mission critical environments. If you are in the process of building or modernizing a control room, we can help you. Contact our team of specialists and designers that will help you build a control center that meets your specific needs and requirements.

Follow us on social media where we share updates on our products and the design trends that are shaping how 911 supervisors are thinking about the future of their control rooms.

Comments